|

|

楼主 |

发表于 2009-6-8 09:28:56

|

显示全部楼层

本帖最后由 木匠乙 于 2009-6-8 09:53 编辑 ; @0 |# t- A% |0 S) }

, @/ [; k0 G1 |( m

OPERATION: ALL BASES

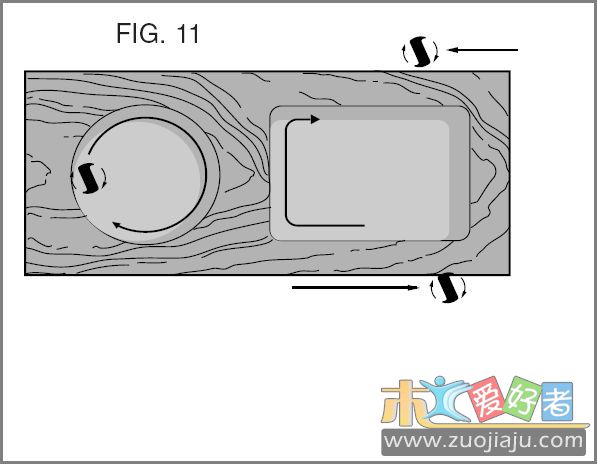

5 i6 N9 T4 l( I+ H* F* d! bDirection Of Feed (Fig. 11)

, J# M/ B9 i8 s* P( V1 m; D! ?; ^进刀方向4 q( x: F# G9 c# C

, |2 \# K2 c) W

& S5 z; L) \, O1 l6 X; d

2 ~6 _) i) J: m( h

3 S, P ], l5 I4 q. H1 |- tThe direction of feed is very important when routing and can make the difference between a successful job and a ruined project. The figures at left show the proper direction of feed for some typical cuts. A general rule to follow is to move the router in a counterclockwise direction on an outside cut and a clockwise direction on an inside cut.. K* e. t2 `6 M/ V, ~% D, k- y

进刀方向很关键,要么漂亮,要么搞砸。图-11给出了正确的进刀方向。 q5 y! Q' n) d5 j6 m7 `$ t

一般来讲,掌握内切顺时针,外切逆时针即可。

/ j9 q! |( e7 ] p, X

J' u! N y6 I7 w& K E1 N; O6 i+ s% K$ \3 g" F7 J& }& g

4 b/ C+ ^# s8 a, W

4 b/ C+ ^# s8 a, W

4 z/ k( ?: X3 `8 ?6 I+ _

2 z) m4 ~& V7 I R2 p

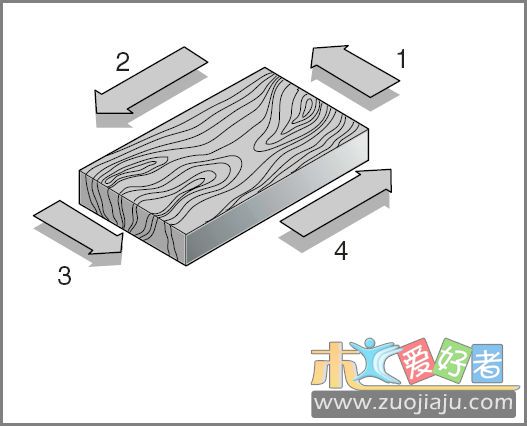

Shape the outside edge of a piece of stock by following these steps:

1 }+ L' S/ C" M+ g1 A) r按以下步骤做边沿成形:% h: o0 F+ r7 H: j" W/ f: z) P I; o

& u. t7 \4 H( |% A

1. Shape the end grain, left to right4 e5 F7 n5 L+ H0 N( O7 R2 e

左到右,修一端头。' s8 H2 C3 U- L1 o6 ]. j

4 F* V/ X, I7 I

2. Shape the straight grain side moving left to right

& ]1 b* B3 U1 J( f# x+ e+ i* e左到右,修一侧边。/ L8 _- m G! g8 g; q

3. Cut the other end grain side

% [9 |& u! |4 n4 p另一端头。) v4 l0 ]* D8 A: F9 N! S: A5 Z

& M0 _0 r6 X5 x0 R4. Finish the remaining straight grain edge1 j" z% y; S7 p7 m

另一侧边。7 n3 h# b, c. _* ^

0 g. j: A6 Q* S) C! x% f

+ n% b' I( r6 C2 F& j! A

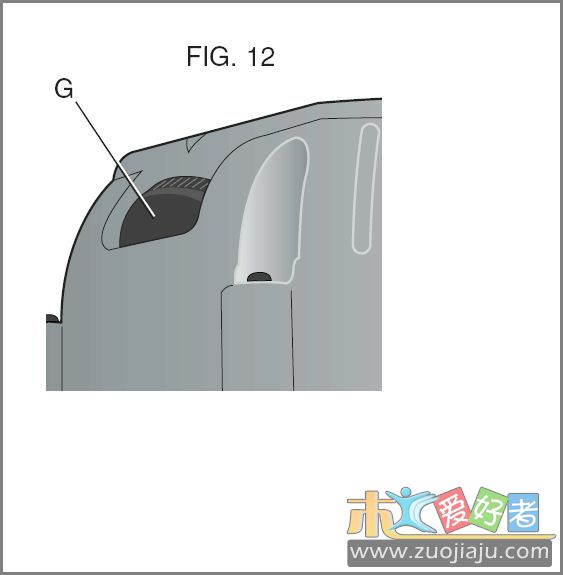

: l+ F8 _& Q) u( XChoosing Router Speed (DW618 only) (Fig. 12)" t, Y9 f8 q+ N; o6 k

调速 (图-12)0 X, D. J5 H0 C

% W5 s% v* |0 J7 m" l

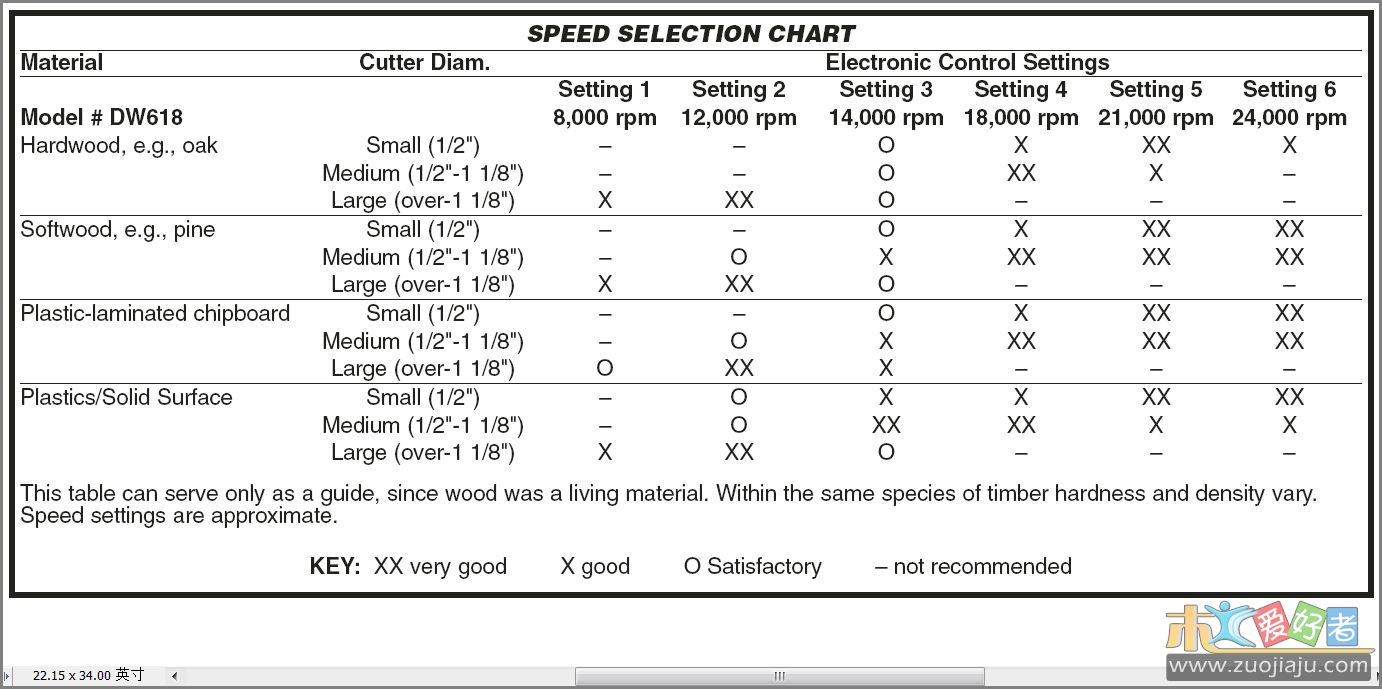

Refer to the chart above to choose a router speed. Turn the speed dial (G) to control router speed.

2 f/ I. x$ x+ m) |+ V$ ]% {2 R. r参照上表选择雕刻机速度。

/ J6 f+ |) ]! L% E( h) G, p转动调速盘(G)调速。

2 j* @/ S1 n: k/ \0 L

5 Z' f( n B, h4 J

# K! H6 J2 ]; G/ e

# K! H6 J2 ]; G/ e

, {- }7 s v( J6 B/ F$ f- L- o5 S6 c1 T* [$ W

) V. K" [8 |6 V: c |

|